-

Substance

- From wood to wood

- Wood

- Processing

-

Research

- At the service of the project

- Sartorial Industry

- Miniature factory

-

Ethics

- Environment

- sustainability

- Zero F

- Certifications

- Reliability

-

Values

- Africa

- Africa Portrait

- ALPI group

-

History

The history of ALPI narrates a manufacturing tradition devoted to excellence, and the story of the Alpi family, starting with Pietro Alpi, who founded the company in 1919.

The first company in the world to industrialize the production process of wood composites, ALPI began as a workshop of fine cabinetry, and rapidly became an industrial leader in the production of decorative surfaces. This breakthrough already began in the 1950s, with the entry of Valerio Alpi in the firm’s management and the launch of capillary distribution across the entire national territory. In 1961 the company presented "ALPIlignum," the first composite veneer, a true revolution made possible by intensive technological research and an important background in fine woodworking, which rapidly led to growth on international markets. In 1975 the group opened its first facility in Cameroon to guarantee a constant supply of raw materials. Starting in the 1980s, with the entry of Vittorio Alpi, prestigious collaborations began with outstanding names in design, developing a deep bond between the company and the world of creativity. ALPI’s ongoing accent on innovation has also led to the collaboration with Piero Lissoni, art director of the company since June 2015.

- COMPANY PROFILE

-

1. Wood

The substance of wood, in all its varieties: ALPI ensures its maximum qualities of expression.

A living, certified, ecosustainable material. ALPI uses poplar, lime wood or ayous, stripped and recomposed in an infinite range of types, finishes and patterns, to respond to all design needs. A unique variety of offerings, with outstanding qualitative characteristics, free of the flaws typical of traditional wood, with unlimited catalogue and bespoke solutions that always provide uniform and constant colors and sizes, replicated over time for multiple applications, on both horizontal and vertical surfaces.

-

1. Workmanship

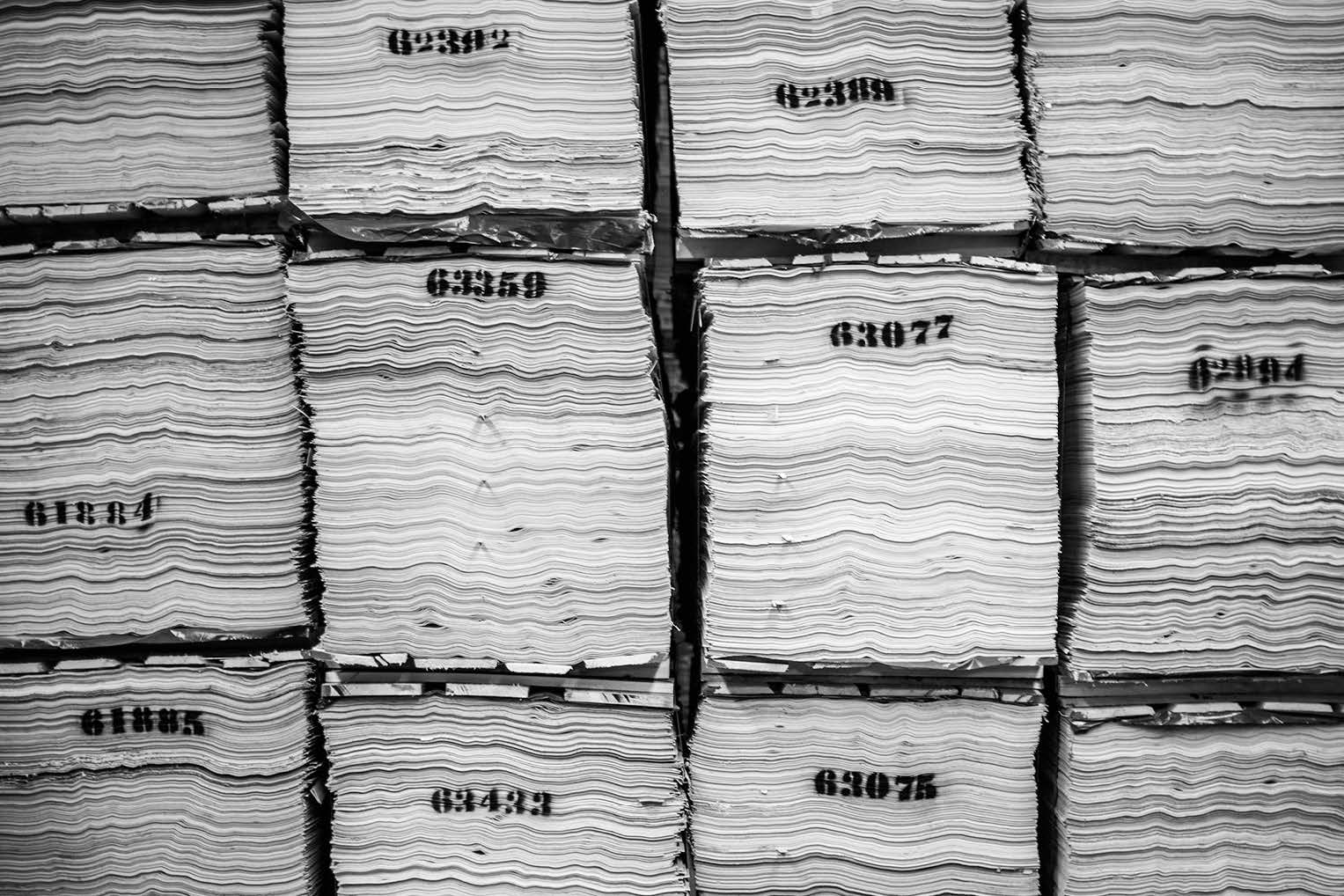

Stripping, dyeing, compositing, gluing, pressing, squaring, shearing, testing…

This is the production sequence of ALPI wood, in which form and substance establish a dialogue with technique and fine workmanship. ALPI breaks down and reassembles wood in infinite varieties, finishes and patterns, thanks to a particular process that slices the wood and dyes it by immersion, then recomposing the dyed sheets to create a new log.

2. At the Service of Design

A partner of leading companies in the luxury, automotive and nautical sectors, as well as prestigious players in the fields of furniture, product design, interior architecture and contract,

ALPI demonstrates its close bond with the world of design in projects for hotels and multi-apartments, retail facilities and public spaces. Through its technical consulting services, ALPI guides clients in every phase of the project, all the way to post-sale services for complete customer assistance.

-

2. Sartorial Industry

Dual dialectic, dual passion: bespoke culture meets and enhances the opportunities offered by the latest cutting-edge technology.

The unique character is in fact the result of a perfect combination of technique and craftsmanship, usually seen as parallel opposites: on the one hand, ALPI means pure innovation, staying ahead of the demands of the market; on the other, it means painstaking custom creations.

-

2. Miniature Factory

The in-house research lab is a true miniature factory, a pilot facility where every process, every piece of machinery is perfectly reproduced to scale.

A catalyst of ideas, where everything begins: a place in which to explore the material, testing its expressive qualities, developing new dimensions, condensing conceptual study and experimentation with forms, structure and aesthetics. Thanks to remarkable investments in R&D and the search for new stylistic and productive trends, ALPI can constantly offer the market new stimuli and new design ideas.

-

3. Sustainability

ALPI operates with complete transparency in terms of environmental and social responsibility, with a constant commitment to excellence in the use of natural resources.

Every ALPI product is made with poplar, lime wood and ayous from certified and sustainable forests, managed with maximum respect for biodiversity. Direct supervision of the entire supply chain guarantees legal and sustainable sourcing of wood and total product traceability. ALPI makes workplace safety one of its main priorities, along with sustainable production methods, including an advanced in-house system for industrial water purification.

-

-

3. Zero F

In line with the strictest international standards, ALPI veneers can be produced in the ZeroF version, with zero added formaldehyde, for the creation of healthy and eco-responsible decorative surfaces.

The result of constant research conducted by ALPI to find solutions that foresee and respond to market demands, ALPI ZeroF products contribute to qualification for LEED (Leadership in Energy and Environmental Design) certification.

-

3. Certifications

FSC® (Forest Stewardship Council®)

Ayous and poplar are the fundamental raw materials for the production of ALPIlignum veneers. The FSC® (FSC®-C004666) certification guarantees sourcing from forests managed in a correct, responsible way in keeping with strict environmental, social and economic standards. In 2023, the forestry concessions managed by the ALPI group in Cameroon obtained FSC® certification under license number FSC-C129174, meaning that ALPI products in wood are available with the FSC 100% label, the highest mark of distinction for FSC®-certified items.

OLB (Origine et Legalité du Bois)

This trademark certifies the legal sourcing and traceability of operations of forestry and industrial transformation of wood in Cameroon. With the OLB (OLB-CERT/COC-60441064) certification granted since in 2009 by Bureau Veritas Certification, ALPI guarantees compliance with regulations regarding forestry management, hygiene, health, workplace safety, compliance with taxation, labor contracts, supply and export of wood. The certification also covers the geographical origin of the wood and its traceability.

Poplar origin certification

The Poplar wood used by ALPI to produce composite wood comes from Italian tree farms. The certification issued by SGS guarantees renewability and the concrete commitment of the company to choices of responsible management of raw materials, also contributing to the utilization of local agricultural resources.

EU Timber Trade Regulation (EUTR) Declaration

Guarantees maximum compliance regarding legality of wood origin, fully complying with EU regulation No. 995/2010 of the European Parliament.3. Reliability

CRIBIS D&B, a company specialized in providing business information on Italian and foreign companies, has assigned ALPI “CRIBIS D&B Rating 1” certification –

the highest level of assessment of financial solidity – indicating a maximum level of reliability as a counterpart in B2B transactions.

4. African Portrait

Thanks to the intuitive vision of Valerio Alpi to build a barge for use as a transportable industrial plant, which was towed to Africa from the port of Ravenna, starting in 1975 ALPI began operation first in Cameroon and then, later, in Ivory Coast.

Today, over 40 years later, the company holds licenses for the management of 500,000 hectares of forest, also fostering the growth of local communities in economic and infrastructural terms. The synergy between the African facilities and the mother company in Modigliana is very close and effective.

-

4. ALPI group

ALPI S.p.A., a leader in the production of decorative composite wood surfaces, was the first company in the world to industrialize this manufacturing process.

ALPI S.p.A., a leader in the production of decorative surfaces in composite wood, was the first company in the world to industrialize this manufacturing process. Founded by Pietro Alpi in 1919, Alpi is the unchallenged technological reference point for the wood sector, with industrial facilities of 180,000 square meters (of which 52,000 indoors) in Italy, and 346,500 (of which 67,000 indoors) in Africa. The operations in Africa began in 1975, the year of the opening of the first plant in Cameroon, to guarantee a constant supply of raw materials. Over the years the ALPI group has expanded its activities to ensure direct control of the entire chain of supply and production, from the log to crafted products, while making a major commitment in the areas of responsible forestry and social development of the territory. Today the ALPI group is one of the main industrial firms in the wood sector in Camerun, operating through the African companies of the group: ALPIcam Industries (peeled wood, plywood, sawn lumber), ALPIcam and Grumcam (sawed lumber and logs) with commercial activities through LES, the Italian commercial force. All the companies operate in perfect synergy with the mother company in Italy.

-